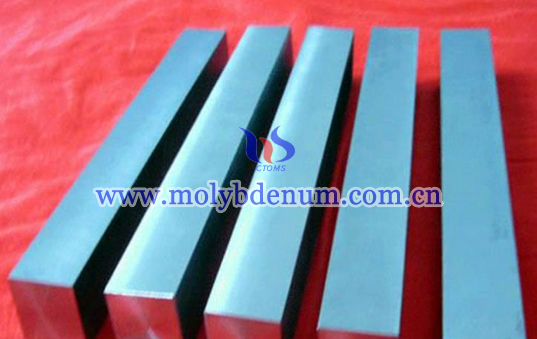

Ground Molybdenum Electrode

Grinding is an important program processing for molybdenum electrode, molybdenum electrodes through grind the surface is smooth and presented a gray metallic luster. Grind is using a special grind wheel which is sticking abrasive to rotate and to cutting metal parts surface. Grind can get rid of burrs, rust, scratches, overlap, weld, trachoma oxide and other macroscopic defects on the surface, to improve the flatness and plating quality of products. Grind suitable for machining all metals and some non-metals, while according to products surface state and quality requirements to grind for one times or several times, after finishing the products surface roughness Ra value can up to 0.4μm, oil polish can get better. Grind effect mainly depends on abrasive characteristics, abrasives quality, grinding wheels toughness and axle rotational speed.

Molybdenum electrode according to surface smoothness and degree of processing can divided into different types, which in accordance with the degree of processing and surface smoothness from high to low is polish molybdenum electrode, ground molybdenum electrode, alkali cleaned molybdenum electrode, sintering molybdenum electrode and forging molybdenum electrodes. Polish molybdenum electrode has smooth and bright surface because the process of it is deepest, and it’s internal and external is a high-quality without crack-free status. Ground molybdenum electrode surface smooth and presented silver gray metallic luster, besides has small dimension error. Alkali cleaned molybdenum electrode surface less smooth than polish molybdenum electrode and ground molybdenum electrode and has gray metallic luster. Forged molybdenum electrode surface is black because there is a layer of oxide on the surface. Sintered molybdenum electrode surface has gray metallic luster, but the surface smoothness compared to other types is the most rough.