Molybdenum Electrode Rods

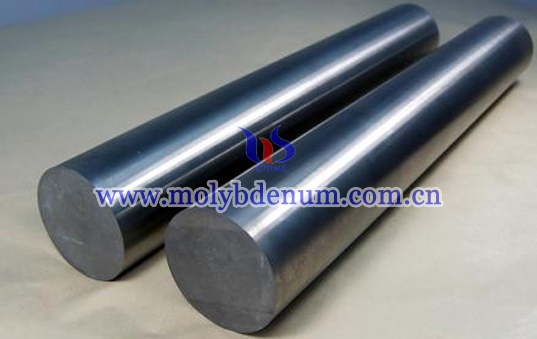

There are two surfaces of molybdenum electrode rods divided from their appearances. One is forging molybdenum electrode rod surface, which is allowed to have oxidize film and slight forging hammer mark. The other one is polished molybdenum electrode rod surface that presents metallic luster and has no oxidized phenomenon notably. The common advantage of these two types provided by our company is that there are no defects in them – no divided layer, no crackle, no burr and no vertical crackle, etc.

Molybdenum electrode is widely used in electric boosting glass kiln electrode and all electric melting. Its surface condition and tolerance can be made differently according to customer's requirement.

The purity of molybdenum electrode is up to 99.93%, and the density is as dense as 10.15g/cu.cm. The temperature using on surface of molybdenum electrode rod can reach 1300℃. Its unite weight is less than 80kg.

When one wants to know a product well, the content of this product is really significant. As to molybdenum electrode, its content percentage is as following:

| Grade | The impurity content accords with GB3876-83 standard | ||||||||

| Fe | Ni | Al | Ca | Si | Mg | C | N | O | |

| Mo-1 | 0.01 | 0.005 | 0.002 | 0.002 | 0.01 | 0.002 | 0.01 | 0.003 | 0.008 |